Shopping Cart

0 item(s) - 0.0000€COPPER PLATED BULLETS

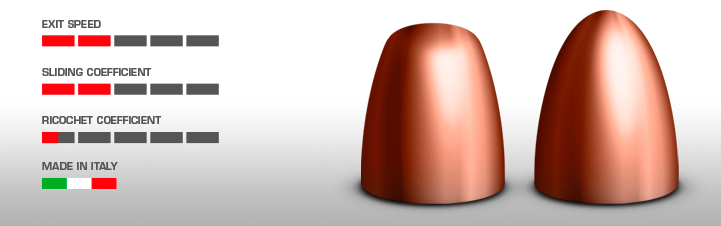

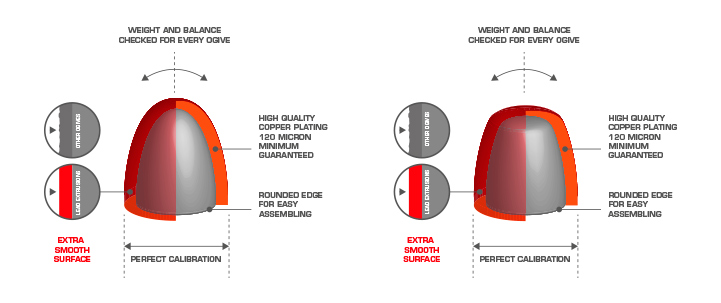

Our COPPER-PLATED BULLETS are built with innovative technologies using a certified lead alloy which, after being extruded and cold molded, is galvanically coated with a thickness of at least 120 microns of copper, equal to 240 microns on the diameter.

Incomparable benefits

Unlike classic jacket coating that detach at the impact, our cladding is produced with galvanic treatment to be firmly joined to the core of the lead bullet. In this way the bullet gets optimum surface hardness, but can crush at the impact for a lower ricochet hazard. Thanks to this total coverage, our bullets do not emit harmful powders at the moment of the shot, whereas most traditional jacketed bullets leave a lead base exposed to the fire power. With Lead Extrusions’ products your weapon will also require less maintenance, as our ogives do not leave any residue in the barrel after the shot.

Controlled Quality

The construction process of our ogives ends with a 100% wire drawing in order to ensure a constant and accurate calibration. Although uncommon in the industry, our process produces a more uniform projectile, with a more accurate diameter and a smooth finish for better shooting performance.

Our revolutionary production process guarantees maximum material uniformity

During the production cycle, every single ogive is checked for weight, balance and caliber

Materials used for the bullets manufacture are certified and controlled at each production stage

Full coating to guarantee total absence of powder emission and lead vapors